Owner-Occupancy Mortgage Fraud: Benefits, Risks, and Legal Workarounds

Embattled Federal Reserve Governor Lisa Cook is facing accusations of mortgage fraud—specifically, owner-occupancy mortgage fraud. The claim is that she took out two mortgages in two states, within two weeks, while designating both properties as her “primary residence.”

If true, it’s a terrible look for someone sitting on the Fed, the very institution tasked with upholding the rules and integrity of our banking system. It’s like the referee secretly betting on the game. That said, we’re all presumed innocent until proven guilty. It’s hard to believe someone so high up in the banking system, with so many eyes on them, would knowingly commit fraud. But stranger things have happened.

Since this site is all about saving, making, and investing more money to achieve financial freedom, let’s use this latest controversy as a springboard to better understand mortgages. After all, most of us rely on them to buy our dream homes. And the lower the interest rate, the more wealth we get to keep.

The Penalty For Mortgage Fraud Can Be Severe

The penalties for owner-occupancy fraud, which falls under the broader umbrella of mortgage fraud, can be surprisingly harsh, even if enforcement is rare. Technically, mortgage fraud is a federal crime under 18 U.S.C. § 1344 (bank fraud), punishable by up to 30 years in prison and fines of up to $1 million. In practice, though, the maximum sentences are typically reserved for large-scale fraud rings, shady brokers, or lenders gaming the system.

Still, lenders have the right to call the loan due immediately through an acceleration clause, which would require the borrower to pay off the entire balance at once or risk foreclosure. They could also retroactively re-price the loan as an investment property mortgage, meaning higher rates and fees, and cut off access to favorable refinancing or future loans.

Beyond the financial hit, the reputational damage can be severe. While the average borrower probably flies under the radar, public figures, brokers, and real estate professionals risk having their credibility torched if they’re caught.

But here’s the reality: owner-occupancy fraud is likely far more common than regulators would admit. The financial incentives are obvious, enforcement is weak, and the dirty little secret is that plenty of borrowers have quietly bent the rules to save money on their mortgages.

The Benefit Of Claiming Two Primary Residences For A Mortgage

The main reason why someone would claim a rental property or vacation property as their primary residence is because lenders offer lower mortgage rates for primary residence borrowers. Whether you are refinancing your mortgage or buying a new property with a mortgage, the average mortgage rate is usually around 50 basis points (0.5%) lower for a primary residence than for an investment property or vacation property mortgage.

On a million dollar mortgage, that amounts to $5,000 a year in interest savings. Over a period of 10 years, if the principal balance remained the same due to an interest only mortgage, that’s $50,000.

In addition, primary residences often get to pay lower property taxes. With the exception of New Jersey and Pennsylvania, virtually every state offers some form of homestead exemption or credit that lowers property taxes for a primary residence. As for Lisa Cook, anyone claiming the homestead tax credit must live in Michigan for at least 183 days to exempt a residence from local school district taxes.

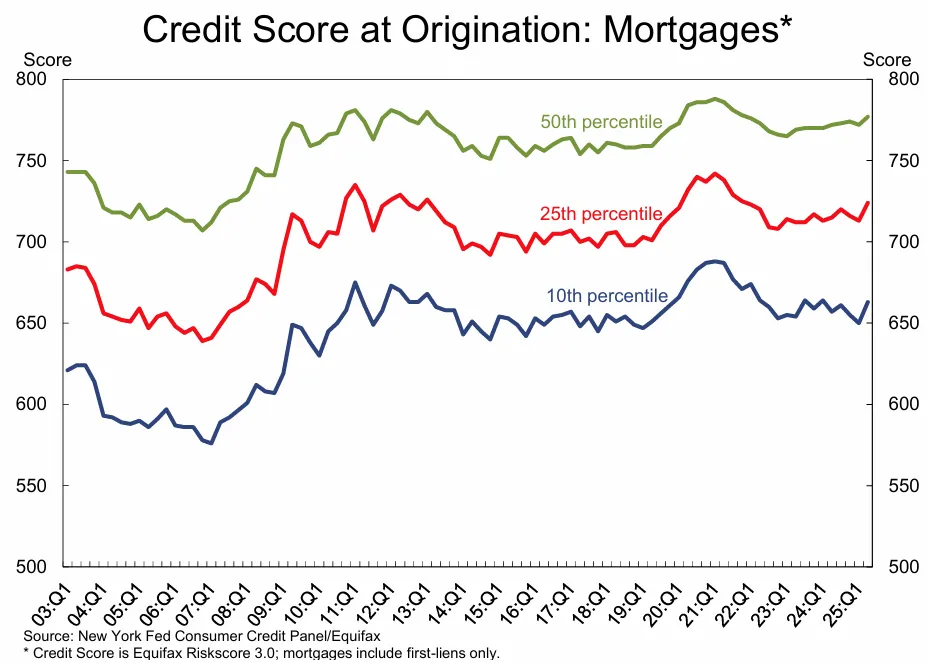

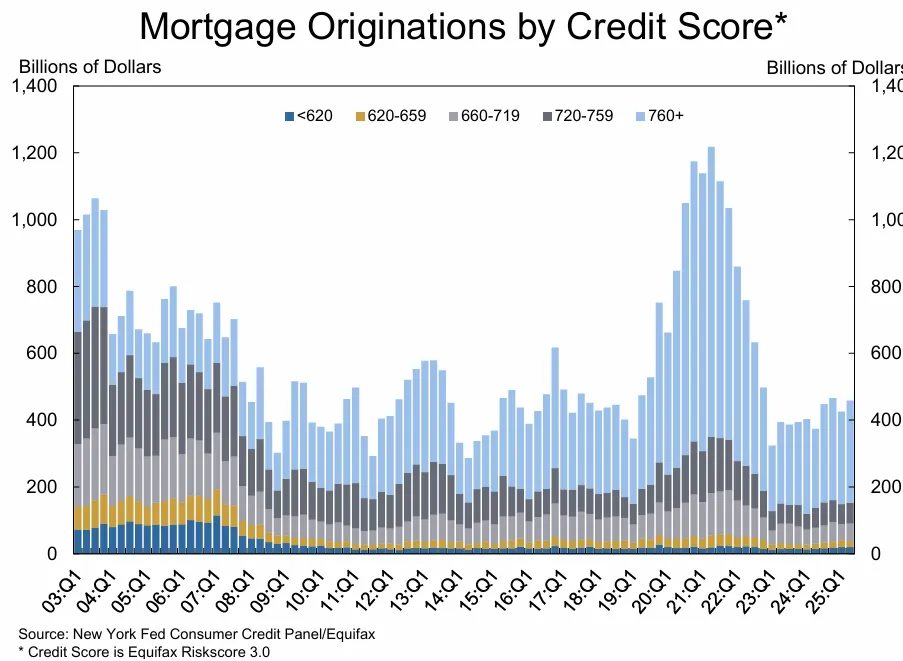

To the lender’s credit, since the 2009 global financial crisis, they have been making mortgage applicants go through the wringer to prove their income, wealth, and credit-worthiness. Lenders have been far stricter since 2009, and don’t want to be left with huge losses again. It would often take me two or three months to get a new mortgage.

Lenders will make you sign a document stating you are refinancing or taking out a new mortgage for a primary residence. You’ll also have to share a utility bill perhaps, but that’s easy to keep in your name.

However, not once, in my more than 15 mortgage applications, has the mortgage officer ever personally come out to verify that I was taking out a primary residence mortgage. And even if they did, how could they prove I wasn’t if I showed up to my empty or not empty rental property? They can’t, unless they hire a private detective to watch my every move for months.

Clearly, the mortgage industry doesn’t have the resources—or the incentive—to crack down hard on owner-occupancy fraud. Loan officers are focused on earning their commissions, while banks are eager to book profits and move on to the next borrower.

Why Primary Residence Mortgages Are Cheaper

From a borrower’s perspective, paying a 0.5% premium for a vacation home or rental property mortgage feels unnecessary. If you’re wealthy—or reckless—enough to buy a vacation property you only use a few weeks a year, you clearly have cash flow. Why should the bank tack on a higher rate?

And with an investment property, you’ve got both your income and rental income from a tenant to cover the loan. Shouldn’t that make the mortgage rate the same, or even lower, than a primary residence loan? You’re less risky given you have an additional source of income.

Unfortunately, borrower logic isn’t lender logic.

- Vacation homes: From the bank’s point of view, these are luxuries, not necessities. When the economy sours, vacation properties are the first to hit foreclosure—as we saw in the 2008–2009 financial crisis. People ditch the lake house before their main roof over their heads. Banks hate holding foreclosed properties, so they pad rates to protect against losses. Foreclosing on and selling off a primary home is easier because the pool of buyers is larger.

- Rental properties: Lenders assume you need tenant income to afford the mortgage. But turnover, vacancies, and late payments make rental income unstable. That’s why banks typically discount reported rental income by ~30% when calculating what you can borrow. What looks like bonus cash to you looks like unreliable income to them.

Meanwhile, a steady W-2 paycheck used to qualify for a primary residence is considered much safer. That’s why primary residence loans get the best pricing.

In short, banks view second homes and rentals as “wants” rather than “needs,” which makes them riskier, and riskier loans always come with a higher price.

The Legal Workaround to Getting a Primary Residence Rate on a Rental

The cleanest way to get a primary residence mortgage rate on a rental property is simple: follow the law. Take out or refinance the loan as a primary residence, then actually live in the property for at least one year. After that, you’re free to rent it out, and you’ll still be enjoying the cheaper rate.

This is one of the big advantages of the U.S. mortgage system. You can lock in a low fixed rate for decades. For instance:

- A 10/1 ARM gives you 10 years of fixed payments. Live there for one year, then rent it out while keeping nine more years at the primary residence rate.

- A 30-year fixed works the same way—live there for a year, then rent it out with 29 years of cheaper debt still in place.

This dovetails with one of my favorite real estate wealth-building strategies: buy a primary residence, live in it for two years, then either sell tax-free (up to $250,000 in gains if single, $500,000 if married) or keep it as a rental. Do this a few times over your life and you can comfortably build 3–6 properties that fund retirement—all while staying 100% compliant with the rules.

That’s very different from applying for two “primary residence” mortgages in two states within two weeks. One is strategic, patient, and legal. The other looks calculated and fraudulent. Yes, timing applications close together in different states makes it harder for lenders to catch, but that’s risky if you’re in a high profile seat.

The Lender Can’t Control Your Life After Closing

Here’s the thing about owner-occupancy fraud: sometimes it’s not fraud at all, it’s just life. You may sign a document promising to live in the property for a year, but circumstances change. Maybe you lose your job three months later. Instead of bleeding cash you don’t have, you move into a friend’s basement and rent out the property to stay afloat.

Is that fraud? I don’t think so. You tried to honor the agreement, but the economy handed you a crap sandwich and you did what you had to do. And let’s be frank, no lender is sending someone to knock on your door and check if you’re still living there. They’re too busy trying to close their next loan.

Or picture this: you buy a home in San Francisco and live there for six months. Then a dream job offer lands in New York City—double the pay and a promotion. You plan to return to San Francisco someday, so you rent out the property at market rates while you’re gone. What bank has the right to tell you to leave it empty, or worse, decline the opportunity? No bank.

Life is unpredictable. Which is why there are probably thousands of cases each year that look like owner-occupancy fraud on paper but are really just people adapting to changing circumstances. The real distinction is intent: did the borrower deliberately misrepresent themselves, or did life force their hand?

You can’t really blame a borrower for thinking ahead either. Many people want to climb the property ladder whenever their finances or circumstances allow. And if the ideal home to raise a family comes along, the temptation is to seize it.

The Bottom Line

There’s a big difference between working the system within the law and outright lying to lenders. One is strategic. The other is fraud.

If the allegations against Lisa Cook are true, it’s not only embarrassing for her but also for the Fed. At the same time, the case highlights a reality few discuss: owner-occupancy fraud is far more common than people think. The incentives are strong, and the enforcement is weak.

Yes, many borrowers who lie are simply trying to save money. But if too many unqualified buyers take on mortgages they can’t comfortably afford, the risk extends beyond the individual. It puts the housing and lending industry on shakier ground when the next downturn arrives.

Readers, what are your thoughts on owner-occupancy fraud as a way to secure a lower primary mortgage rate? Should lenders tack on a 50-basis-point (or higher) premium for rental and vacation properties? And do you believe the Fed governor knowingly committed mortgage fraud just to save money?

Invest In Real Estate Without Needing A Mortgage

If you want to diversify into real estate without taking on a mortgage, consider Fundrise—a platform that lets you invest 100% passively in built-to-rent residential and industrial properties. With about $3 billion in private real estate assets under management, Fundrise primarily targets the Sunbelt region, where valuations are lower and yields tend to be higher.

As the Federal Reserve embarks on another multi-year interest rate cut cycle, real estate demand is likely to rebound. The sharp rise in mortgage rates from 2022–2025 has dramatically slowed new construction, which could lead to greater rent pressure in 2026 and beyond. That’s why it may make sense to invest today before rent inflation potentially accelerates.

I’ve personally invested over $500,000 in a couple of Fundrise funds, and they’ve been both a trusted partner and long-time sponsor of Financial Samurai. With just a $10 minimum, diversifying your portfolio into real estate has never been easier.

Subscribe To Financial Samurai

Pick up a copy of my USA TODAY national bestseller, Millionaire Milestones: Simple Steps to Seven Figures. I’ve distilled over 30 years of financial experience to help you build more wealth than 94% of the population and break free sooner. A core part of becoming a millionaire is investing in real estate.

Listen and subscribe to The Financial Samurai podcast on Apple or Spotify. I interview experts in their respective fields and discuss some of the most interesting topics on this site. Your shares, ratings, and reviews are appreciated.

To expedite your journey to financial freedom, join over 60,000 others and subscribe to the free Financial Samurai newsletter. You can also get my posts in your e-mail inbox as soon as they come out by signing up here. Financial Samurai is among the largest independently-owned personal finance websites, established in 2009. Everything is written based on firsthand experience and expertise.

Source: Owner-Occupancy Mortgage Fraud: Benefits, Risks, and Legal Workarounds